Management and talent

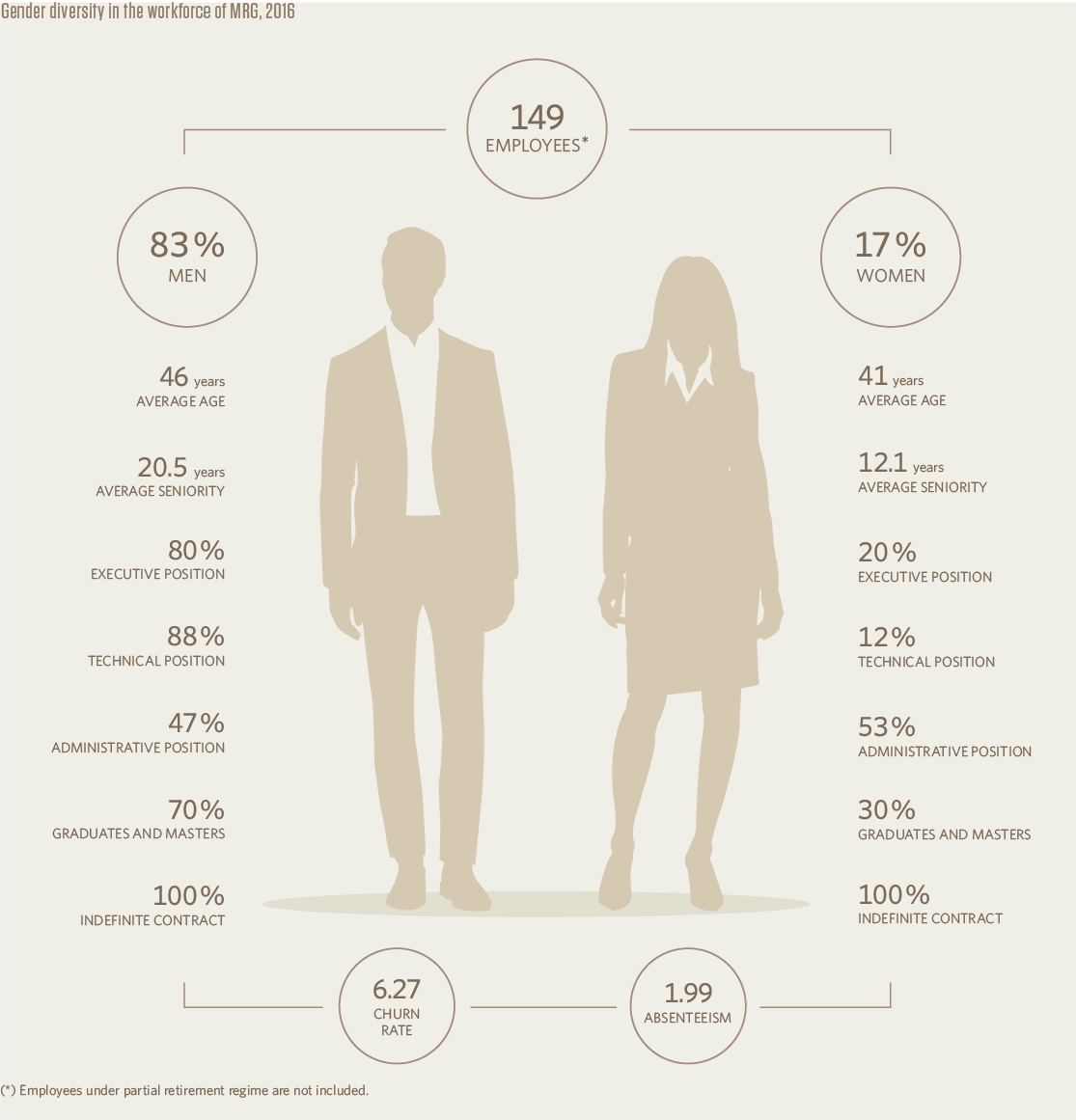

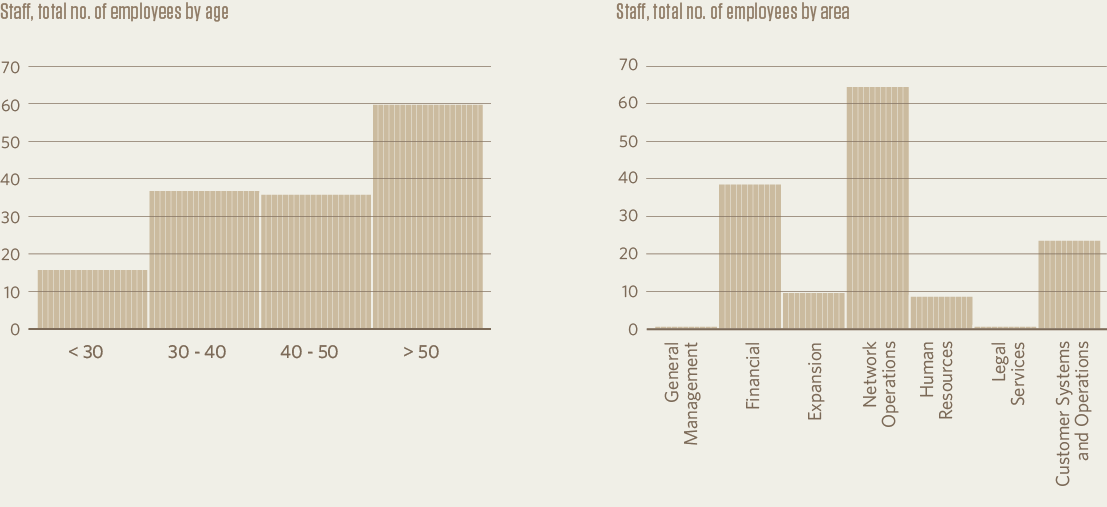

The low turnover rate indicates the degree of satisfaction within our team, with an efficient, right-sized workforce of 149 employees with an average of 19 years in the gas sector.

The policies applied and dynamic knowledge management oriented to develop the potential of the employees have been keys to the proper scaling of the deployment; 88% of the employees have occupied technical or managerial positions.

The clear commitment of the company to talent has made sure that new additions have increased quantitatively and qualitatively in 5%, with an increasingly greater portion of graduate employees.

This year, and as a result of the mentoring program conducted previously with senior and middle management, Madrileña Red de Gas has begun the planning of the follow-up programmes. We have already completed the preparatory work to ensure that in the next financial year the first effective successions will take place in different areas of the company.

The commitment acquired by MRG to carry out responsible management will ensure that its team works on the basis of the establishment of trust for the benefit of the welfare of the employee and the success of the company. This commitment has enabled those employees who, by mutual agreement with the company, and having reached the age of 61, want to combine continuation in a part-time job (15% of working time) with the receipt of a retirement pension, to be eligible for a part-time contract allowing the company to achieve the renewal of the deployment. The incorporation of new employees is performed by replacement contracts, with consequent rejuvenation of the team, an increase in the average level of training of employees, an improvement of the working environment, growth of the production level and a decrease in sick leave.

Development

In relation to training, Madrileña Red de Gas sees it as a main objective for this year to cover three principal needs: corporate training, business training and training in languages, and all the resources and efforts needed to achieve this have been assigned.

Corporate training

Within our commitment to corporate social responsibility, we have worked very actively on projects for the protection of personal data and the prevention of offences. This is shown by our response to the training needs that arise from both. One third of the total cost incurred in this financial year corresponds to this training.

Business training

Due to the evolution of the company, another challenge we have had to face was the coverage of the training needs that have arisen as a result of change management.

In Madrileña Red de Gas, we consider that the people who know the business best are the employees themselves. That is why we have opted to make use of the experience and knowledge of our team, by promoting and facilitating its transmission across the entire deployment.

In order to respond to the needs of 118 employees, we have provided specific courses on LPG and CNG to all those requiring a greater understanding for the new challenges posed by the company. We have also conducted new gas distribution courses.

Language training

This year, we have focussed efforts aimed at training in languages, as the third axis to be pursued within Madrileña Red de Gas. As a company owned by foreign investment funds, with the aim of continuing to improve the communication with our investors, we have earmarked around 1,000 hours to the progressive improvement of the English of all those employees who, according to their working requirements, have a need for it.

Safety and prevention

Safety and health are fundamental values in our corporate culture. We understand that they are a responsibility of each and every one of the employees who are part of the team of Madrileña Red de Gas. For this reason, we integrate them both in the everyday activity of the company, so that each employee can, and must, help improve the safety of his colleagues. As a reaffirmation of the commitment of Madrileña Red de Gas to its employees and other stakeholders, we have renewed with Tüv Rheinland our certification as a company certified with the seal of business excellence in prevention OHSAS 18001.

For us the prevention management system constitutes the firmest expression of our policy on industrial safety and occupational risk prevention. It includes all processes that involve the need to integrate criteria on safety and prevention of occupational risks. Its implementation ensures:

- Promotion and consolidation of a culture of safety and risk prevention and integration of that culture in the various processes.

- Commitment to compliance with the legal requirements.

- Periodic assessment of the risks and planning for safety and the prevention of occupational risks.

- Measurement and monitoring of the performance of prevention processes.

- Increase in the effectiveness and efficiency of the organisation in the achievement of its objectives.

- Continuous improvement of processes, products, efficiency, etc.

- Prevention and minimisation of accidents and incidents.

- Improvement of the safety awareness and training of our own employees and contractors.

The basic structure of criteria for safety and risk prevention management is part of the philosophy of using the synergies associated with the integrated management system for prevention, environment and quality of Madrileña Red de Gas. This structure is complemented by specific prevention procedures that have been considered necessary, such as the evaluation of occupational hazards, risk prevention activities given the potential presence of explosive atmospheres, measures for safety during work in confined premises, work permits or the prevention of risks in connection with propane from third-party networks, etc.

In addition, Madrileña Red de Gas annually updates its occupational risk prevention plan, giving continuity to its culture of change management, with the objective of constantly renewing its commitment to safety and the prevention of emerging risks. The health and safety management system of Madrileña Red de Gas establishes specific prevention targets for each financial year. Today, they are intended to maintain the validity of the management model, the actions of operational control, the implementation of preventive actions, the promotion of risk information, preventive measures and emergency or training in safety and health surveillance, in application of the cycle of continuous improvement. This generates a framework for the monitoring of more than 30 prevention indicators associated with the processes of prevention management that make it possible to track performance. In addition, the performance of periodic audits facilitates the identification of possible deviations and opportunities for improvement.

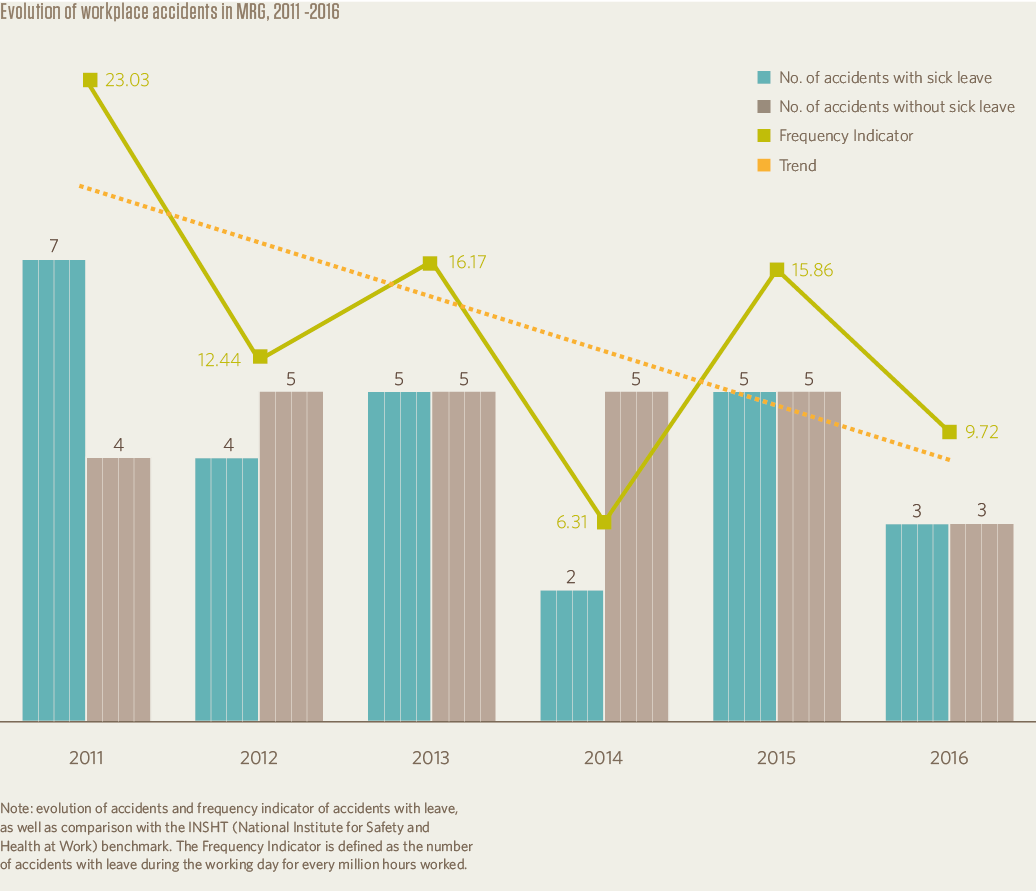

Madrileña Red de Gas continues to cooperate with public administrations, maintaining its adherence to the bonus system established by Royal Decree 404/2010 for companies with low work accident rates.

In this financial year, we have completed the review of the risk assessment work of the headquarters and workplaces, according to the methodology of the external prevention service, through the application of quantitative and qualitative techniques.

This assessment is carried out in several stages. The first focuses on informative work of raising awareness about these risks. We have conducted surveys based on the FPSICO 3.0 methodology of the Spanish National Institute of Safety and Hygiene at Work (INSHT) and in the method of analysis of the working conditions of the French Agency ANACT (Agence Nationale pour l’Amélioration des Conditions de Travail) for the improvement of working conditions. 69% of employees have participated in them, and we have performed surveys modelled on the basic assessment of shift work and night shift defined by the external prevention service. We have also conducted semi-structured interviews on an individual or group basis on working conditions, supervised or semi-supervised, in which 97% of the workforce have taken part.

The results of this assessment have allowed us to take preventive measures aimed to improve working conditions in connection with psychosocial risk factors.

The activities carried out by Madrileña Red de Gas are covered in Annex I of Royal Decree 39/97, the Regulation on Prevention Services. We have established a new external prevention service arrangement with Previlabor for the four preventive specialties of safety at work, industrial hygiene, ergonomics and psychosociology and health surveillance. An agreement with that institution covers the entire range of specific prevention requirements.

In order to facilitate compliance with the specific requirements arising from the implementation of the OHSAS 18001 standard, Madrileña Red de Gas has a service for the identification and assessment of the legal requirements for safety and prevention of occupational risks.

On the other hand, the commissioning of LNG plants has required specific actions in the field of safety, transport of dangerous goods by road (ADR) and prevention of occupational risks. Among these, the most relevant are:

- Documentation of protection against explosions in each of the facilities, with their corresponding verification of explosive atmospheres.

- Self-protection plans of each of the facilities, training for employees and implementation of these plans through emergency drills.

- Extraordinary allocation of personal protective equipment for the prevention of the risk of contact with cryogenic substances.

- Fact sheet on risk, preventive measures and emergency measures in LNG plants, for contractors who perform their maintenance.

- Implementation of the requirement of approval of suppliers of “LNG satellite plant technicians”, promoted by the sector.

- Dissemination among the employees of Madrileña Red de Gas of the Guide on “Best practices of safety and environmental protection in satellite LNG plants”.

- Hiring of a new service of safety adviser for the transport of dangerous goods by road (ADR). For the first time the statutory annual report for 2015 has been lodged with the Ministry of Transport and Infrastructure of the Community of Madrid.

- Procedure for the unloading of LNG tankers specific for each installation. Definition of the contents of “harbour letters for total and partial unloading” under the regulations, as well as list of safety checks during unloading.

- Regulatory reports of the Safety Adviser on the first unloading in the plants.

- Drafting and publication of the criteria in the event of accident or incident that may occur during the transport, loading or unloading of dangerous goods.

- Publication of the safety data sheets of chemicals from natural gas in its different phases, including odorised with THT.

In addition, and following the policy of Madrileña Red de Gas to provide periodic information on the prevention of occupational hazards to all stakeholders, we have reviewed the information sheet on risks, preventive measures and emergency measures of the regulation and metering stations (RMS), mainly aimed at our own employees and contractors. We have also published a prevention newsletter which has disseminated the most relevant news in our field.

In relation to the exchange of documentation on prevention, carried out through external documentation for prevention control, it has been necessary to define new criteria of approval of supplier personnel for foreign employees, self-employed employees and the personnel responsible for performing LPG conversions. We have also expanded the scope of documentary supervision to heavy machinery. Currently, this service is monitoring documentary control of a total of 79 contractors and subcontractors as well as of 799 employees; the monitored volume is more than 7,586 documents.

These documentary checks are completed through direct supervisions in the field, which verify the effective implementation of a wide range of preventive measures and also whether the documentation provided is correct. The results of these checks are communicated to the contractors for their knowledge and the implementation of improvements. At the same time, MRG maintains regular follow-up meetings with supervisors in the field that promote regular dialogue with the prevention technicians of the main contractors, so as to establish ways of effective communication of information.

In addition, we continue to enhance the content available on the information channel for prevention which, even though it was created to facilitate access to the information for personnel, has now been adapted so that the main contractors can access updated editions of information on preventing occupational risks.

It is noteworthy that the objectives of MRG include a decline in the number of accidents at work; to do this, we have renewed our commitments in two directions:

- Firm and constant commitment to training and information on prevention of occupational risks for employees to achieve greater awareness of the employees.

- Investigation of accidents at work and, if they occur, additional preventive measures.

In the field of collective protections, personal protective equipment (PPE) and clothing, Madrileña Red de Gas maintains a direct communication channel with our suppliers of equipment and materials. This helps us to keep up to date with regards to new materials and equipment that are put on the market, as also on the courses for training the suppliers themselves on new equipment and its proper use.

In Madrileña Red de Gas we have concluded a model, which has been negotiated with the representation of employees on the management of preventive resources. This includes the carrying out of those functions by an external prevention service to cover specific situations in which it was not possible to do so with our own personnel.

On the other hand, we have defined a system of prevention work designed for particularly hazardous work, and it has also been disseminated among our contractors.

In addition, and in relation to the activities for expanding the distribution networks of natural gas, in Madrileña Red de Gas we have defined the criteria for the prevention of occupational risks which must be taken into account while working with propane from third-party networks.

In relation to the policy of prevention of risks in activities with the potential presence of explosive atmospheres (ATEX), the implementation of these policies has been achieved in all of the facilities. The scope of this project has been extended to remotely controlled valves, and to all the regulation and metering stations (RMS) of the semi-ring, recently transferred to Madrileña Red de Gas.

On the other hand, and in connection with the new legislation, we have reviewed the criteria on meters with explosive atmosphere marking intended for commercial and industrial applications, and we have begun the process of adaptation of our internal rules, manuals, etc.

Finally, Madrileña Red de Gas continues to participate in the sectoral committee, where it has established a collaboration with INSHT. The first fruit of this cooperation has been the publication of the “Technical prevention note NTP 1058 Sector gas: occupational hazards in installations for the storage, transport and distribution of gas”. We have also attended business forums, such as the safety congress of SEDIGAS where information on best practices related to the prevention of occupational risks is shared.